-

Build up Subfloor to Match ex. Hardwood Floor Height – Oli and Summer

Hello Joe,

Thank you very much for all your amazing videos and building this fantastic Laminate University! Could you please help us with the following questions regarding prepping subfloor for LVP installation (each plank is 60″x9″, 5mm SPC Core + 1.5mm IXPE pad)?

Background:

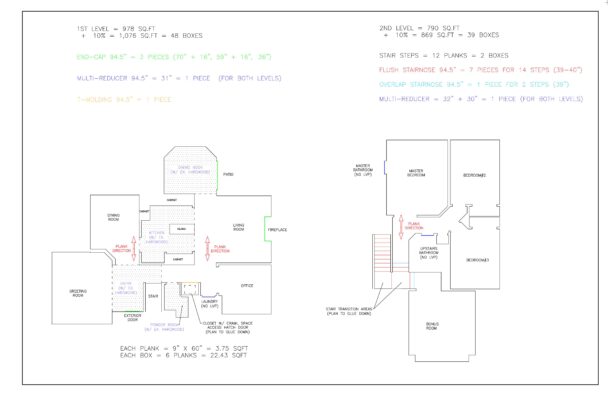

– We have ex. OSB subfloor for the 1st level. There are ex. hardwood floors in the entry area, kitchen, dining nook, and powder room (please see the attached floor plan that we created before).

– We have removed the carpet and are planning to add a 23/32″ OSB underlayment to match the ex. hardwood floor height (see the attached photos). This way we can avoid lowering all interior door frames and the mess of removing ex. glued-down hardwood floor. We have checked the exterior door clearance per your instructions.

Questions:

1. Should we leave a gap between the new OSB underlayment sheets and ex. hardwoods/walls?

2. We bought a 4×8 test OSB piece and cut it into half in the store. After screwing it down next to the ex. hardwood, we found that the factory edge is thicker and became a hump. But the new cut edge is pretty flush with the ex. hardwood (see the attached photo). Is it better to sand down the new OSB sheet joints with an edger sander before working on any dips? Which grit sandpaper is recommended?

3. With ex. 3/4″ subfloor and new 23/32″ OSB underlayment, would 1/4 in. x 1-1/4 in. staples be enough? How much PSI for the air compressor? Will the staples affect any needed sanding if there are any humps in the new OSB underlayment?

4. We have some minor dips in the ex. hardwood floor (about 1/16”) within a 6’ radius (see the attached photo). This meets the LVP specs. Is it worth just filling these dips with Henry 549 while doing all the prep work?

Thank you very much!!

Oli and Summer

Log in to reply.